What is Medical Contract Manufacturing?

Medical contract manufacturing allows companies to outsource the production of medical devices and components to specialized third-party manufacturers. These manufacturers have expertise in various aspects of production, such as molding, assembly, and design, and also often provide packaging, logistics management, quality assurance, and other supporting services.

At Pilgrim Harp, we offer medical contract manufacturing services that can be customized to your company’s unique requirements. From start to finish, we handle every step of the process to ensure you get the medical components or assemblies you need.

Medical Contract Manufacturing We Handle

Pilgrim Harp specializes in a range of processes tailored to meet the medical industry’s specific needs. Our capabilities include:

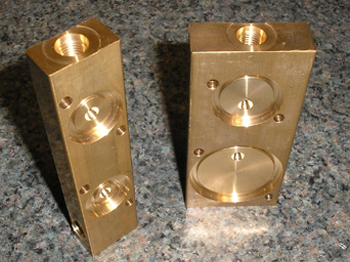

- CNC Machining. We can produce brass and aluminum medical device components and more.

- Castings. Our expertise in permanent mold castings, investment castings, and other methods ensures high-quality results.

- Forgings. We work with a variety of materials, such as aluminum alloys, bronze, carbon steel, copper alloys, stainless steel, and more.

- Stampings. Our precision stamping capabilities allow us to produce quality healthcare components.

- Injection Molded Components. We specialize in producing multi-component assemblies using injection molding.

We are dedicated to delivering the highest quality products with on-time delivery. Our representatives are in constant contact with our global partner factories, and we conduct regular quality system audits to ensure every part of the production process meets our rigorous standards.

Our Partner Factories

As a contract manufacturer, Pilgrim Harp partners with highly skilled factories in the U.S., China, Taiwan, and India to meet the demanding requirements of the medical device industry. These factories can reliably manufacture precise components for medical devices and other healthcare applications. Additionally, we offer engineering support, design consultation, tooling, mold development, R&D, computer automation, and process control.

Each of our partner factories holds industry certifications such as ISO 9001:2015, AS9100:2016, or IATF 16949, ensuring they meet strict international quality standards. After production, all products undergo additional quality checks both at the producing facility and at Pilgrim Harp’s Avon Lake, Ohio factory. Because we handle the entire process, you can be confident knowing you’ll receive exactly what you expect, with no compromises.

Contact Pilgrim Harp for All Your Medical Contract Manufacturing Needs

Pilgrim Harp has the expertise and resources to handle all of your medical contract manufacturing requirements. With our partner factories, comprehensive services, and dedication to quality, we can provide customized solutions designed to meet your specific needs. Working with Pilgrim Harp helps save you time and needless headaches, and ensures the best results for your medical products.

For more information about our medical contract manufacturing services and how we can support your business, contact Pilgrim Harp today.