How to Eliminate Inspection from My Dock-to-Stock Process

Pilgrim Harp handles all inspection requirements so that you, the customer, don’t have to.

Quality Begins At the Source

- Advanced Quality Planning (AQP process) – All quality requirements for new projects are pre-determined prior to first article sampling, including First Article Inspection and PPAP preparation.

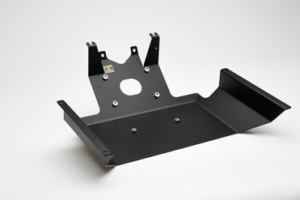

- All products go through in-process and final inspection at the PH source factory prior to shipping to the PH warehouse in Avon, Ohio.

- The majority of Pilgrim Harp partner factories are certified to ISO or greater

Trust But Verify

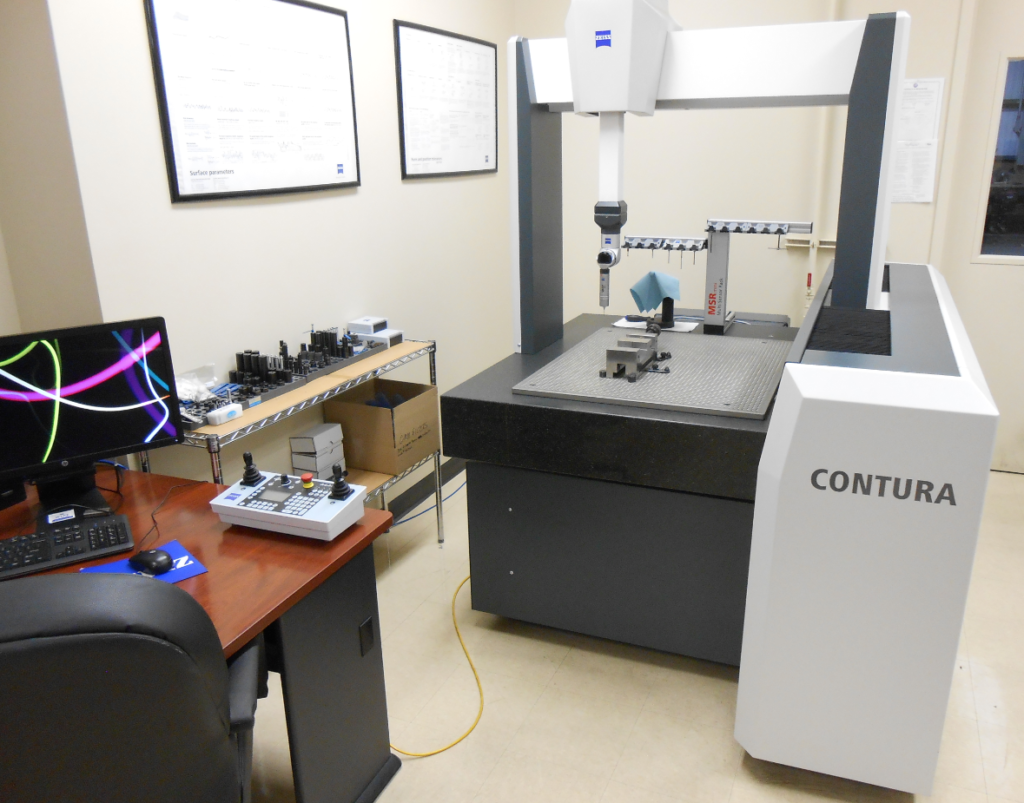

- PH Quality Lab – Upon receipt of product at Pilgrim Harp, sample lot inspections are conducted to verify:

- Dimensional conformity based on customer blueprint drawings:

- Optical vision machine inspection

- CMM and precision measuring devices

- Customized/functional gage inspection

- Packaging conformity per customer requirements

- Raw material and surface treatment conformity

- Non-ferrous material chemical analysis

- Raw material hardness testing

- Documentation management:

- Raw material certification

- Process, coating, and treatment certification

- Dimensional inspection reports

- Dimensional conformity based on customer blueprint drawings:

- Pilgrim Harp source factory auditing – Customer auditing requirements can be handled by Pilgrim Harp staff to save time and avoid costly travel expenses. Quality system auditing and specific project review is conducted by PH staff members onsite at the Pilgrim Harp partner source factories

- Pilgrim Harp’s quality management system is certified to ISO 9001:2015 and AS9120 Rev. B