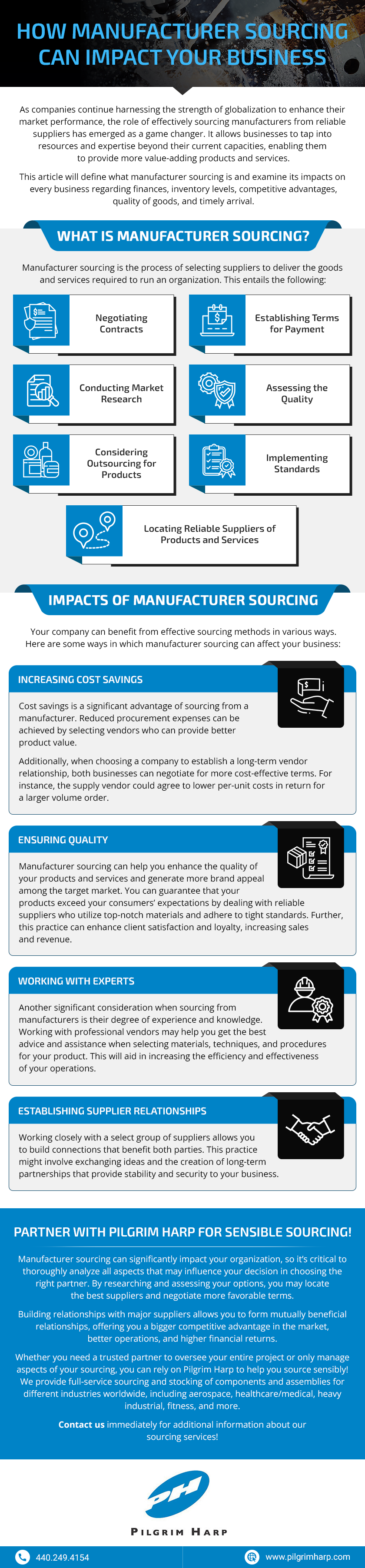

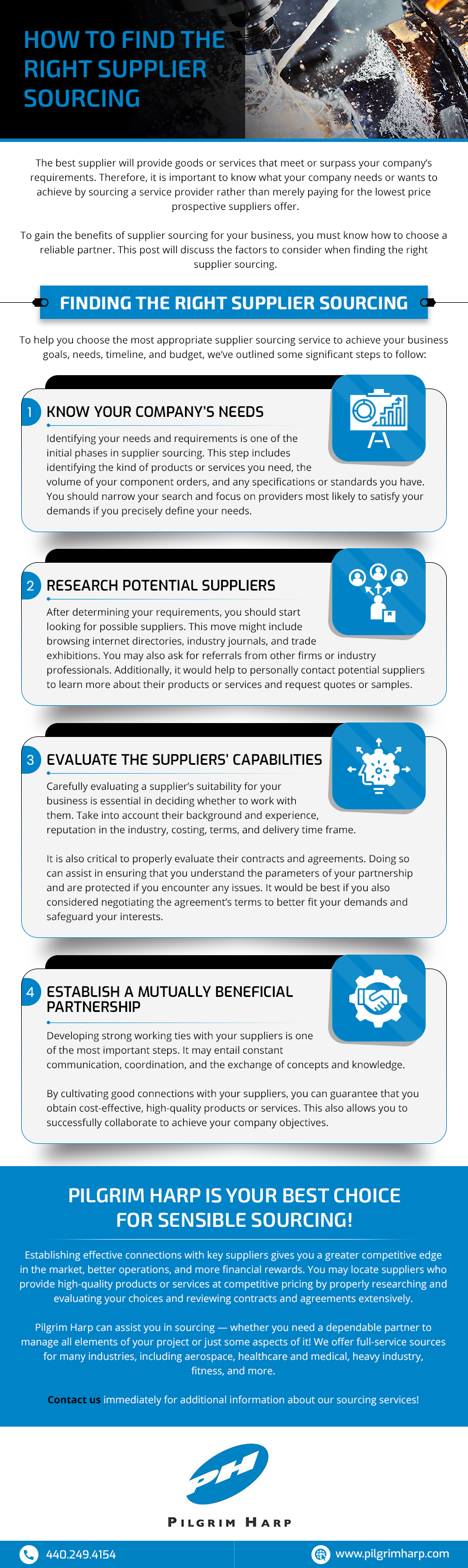

Procurement Excellence: Integrating and Optimizing Your Supply Chain Strategy

Leave a CommentWell-established procurement systems are crucial in supply chain management as they ensure the timely acquisition of goods and services at optimal prices. This streamlines the purchasing process, reducing costs and mitigating risks associated with supplier relationships. Effective procurement strategies also enable companies to maintain inventory levels, meet customer demands, and uphold quality standards.

In this article, we will examine what makes a procurement system effective. We will also look at how businesses can optimize their procurement processes to enhance overall supply chain performance.

Elements of a Robust Procurement Strategy

The following elements allow companies to develop a comprehensive procurement strategy that enhances overall supply chain performance:

Supplier Relationship Management (SRM)

SRM is about fostering mutually beneficial partnerships built on trust, transparency, and collaboration. It starts with rigorous supplier selection processes, where vendors are evaluated on cost, reliability, quality, and ethical practices.

Strategic Sourcing

Strategic sourcing is a proactive approach that encompasses analyzing market trends, assessing supplier capabilities, and considering factors like quality, reliability, and sustainability. It also includes fostering long-term relationships with key suppliers, which can lead to preferential treatment and access to the latest technologies.

Risk Management

Effective risk management is paramount for maintaining supply chain continuity in today’s volatile business environment. This involves identifying potential risks — including supplier bankruptcy, geopolitical instability, or natural disasters — and developing strategies to mitigate their impact.

Process Optimization

Procurement processes can often be complex and inefficient, resulting in delays, errors, and increased costs. Process optimization aims to streamline these processes to improve efficiency, reduce cycle times, and enhance overall effectiveness. This may involve standardizing procedures, automating manual tasks, and implementing technology solutions like e-procurement platforms.

Compliance and Ethics

Compliance with legal and regulatory requirements is non-negotiable in procurement, but ethical factors are equally important. Companies must ensure that their procurement practices adhere to laws governing anti-corruption, competition, and data privacy. Additionally, ethical sourcing practices are increasingly important for maintaining brand reputation and stakeholder trust.

Performance Measurement and Continuous Improvement

Monitoring key performance indicators (KPIs) and metrics is essential for evaluating procurement strategies’ effectiveness and identifying improvement areas. Common KPIs include cost savings, supplier performance, and contract compliance.

Benefits of Integrating Procurement and Supply Chain Management

Combining procurement and supply chain management into an integrated function offers the following benefits:

Cost Savings

Companies can negotiate significantly lower supplier prices by combining purchase volumes and utilizing economies of scale. They can also improve inventory coordination, lower carrying costs, and minimize stockouts or surplus inventory. This can result in substantial cost savings for the organization, positively impacting the bottom line and improving overall profitability.

Enhanced Collaboration

Integration promotes greater collaboration between procurement and supply chain teams, leading to more efficient coordination and communication. Businesses that align goals and share information can adapt more swiftly to changes in demand or supply. This approach can lower lead times and enhance overall responsiveness to client demands.

Improved Supplier Relationships

Integrating procurement and supply chain management facilitates stronger relationships with suppliers. Organizations can better understand supplier capabilities and negotiate more favorable terms by involving procurement experts in supply chain decision-making processes. This leads to increased supplier satisfaction, better performance, and a more reliable supply base.

Enhanced Visibility and Control

Integration increases insight into procurement and supply chain processes, allowing companies to analyze performance, monitor compliance, and discover areas for improvement. They are also better equipped to see bottlenecks or inefficiencies in the processes. This enables proactive decision-making and the ability to address issues before they escalate.

Strategic Alignment

Integrating procurement with supply chain management ensures alignment between purchasing decisions and overall business objectives. This enables procurement teams to prioritize initiatives most effectively contributing to the right strategic direction. For example, if the goal is to reduce the time to market for new products, procurement can focus on selecting suppliers that offer faster lead times.

Invest in Strategic Supply Chain Solutions With Pilgrim Harp!

At Pilgrim Harp, we offer tailored supply chain solutions designed to propel your business forward. Our services include nearshoring, LCC sourcing, and supplier management strategies. Backed by years of industry expertise, we are your trusted partner in driving sustainable growth and achieving your business objectives.

Contact us today to learn more about our services!